Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

In recent years all Natural-flake graphite companies are looking for ways to add value to their run-of-mill graphite concentrates.

With the growth of electric vehicle (EV) industry, to upgrade the natural-flake graphite for lithium-ion batteries application will be a good choice. For lithium-ion battery anodes, current industry practice is to mill and spheronize graphite concentrate prior to purification with hydrofluoric acid (HF). Typical yield of anode graphite from this process is 35%.

LNPE Powder Equipment Company has LNPE has invented a new type of graphite spheroidizing machine that can increase the yield to 60%.

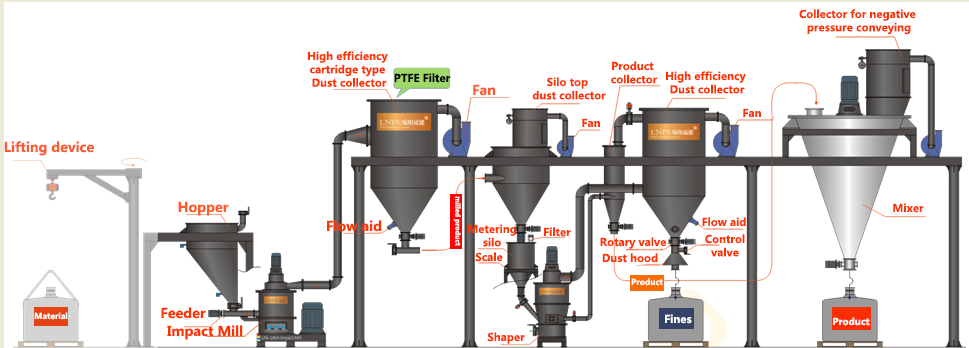

The graphite grinding and shaping production line developed by LNPE is mainly composed of 1 Impact Mill, 8 shapers, 1 finished product mixing system and supporting Pneumatic Conveying System. The production line runs fully sealed, under negative pressure, which significantly reduces the generation of process dust.

Process Flow of LNPE Natural Graphite Grinding and Shaping production line

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.